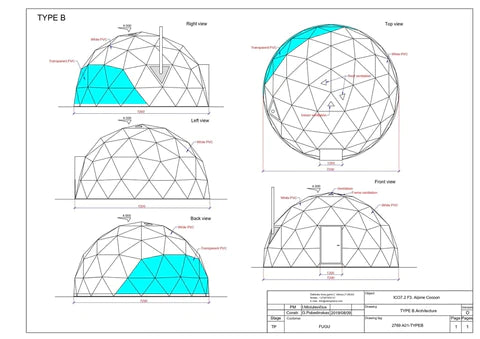

Insulated Geodesic Dome All-Year Use

The Challenge is to design and develop the insulated dome envelope suitable for all-year-round use in the mountains with temperature variations, high loads of rain and snow.

One of the main tasks was to develop the custom solution for the condensation at the area of the panoramic window to avoid moisture on the oak struts of the carcass of the glamping dome.

Solution 7-layer custom-designed insulated envelope made to extract moisture from the envelope itself and extract moisture from the inside of the dome.

The panoramic window oak struts are made with inclusive cut polycarbonate stripes that adjoin with the window to avoid condensation and moisture rest on the wood.

Price for All Insulated Dome Models

How to Build an Insulated Geodesic Dome?

Insulated Geodesic Dome Specifications

| Category | Glamping Domes |

| Country | France |

| Type | Contemporary design insulated building |

| Usage | Nature hotel, Glamping |

| Insulating | Insulated |

| Diameter | 7,2 |

| Size | D7,2m, H3,5 |

| Floor Area m2 | 41 |

| Snow / Wind Loads | Standart 1.6 kN / 34 m/s |

| Frame system | STAR Classic Zn, WOOD Pine C24 RAL, Insulating PIR |

| Cover | PVC tarpaulin |

| Product | Icosahedron Dome ICO7,2 F3 3/7 STAR/WOOD/PIR/PVC |

Frame: Frame parts are not visible when the frame is covered with panels from the outside and inside. C24 class structural wood is used. Double-layer STAR connectors galvanized. Insulation layer inside, between interior plywood panels and external OSB panels.

The visible frame parts of the panoramic window are made of ash wood. STAR connectors stainless steel. There are polycarbonate spacers between the ash wood and the PVC coating.

Facade: The facade of the dome is multi-layered. External coating: PVC cover, diffusion film, OSB board.

Insulation: The dome insulation layer is 50 mm PIR. Fireproof class B-s1, d0.

FF-PIR thermal insulation panels are made of rigid polyisocyanurate (polyurethane) foam (PIR) core and are covered with multi-layer aluminum foil on both sides.

The extremely low thermal conductivity of these panels (λD = 0.023 W/(mK)) allows the thickness of structures to be reduced by up to 2 times. This not only saves space and usable area in the premises, but also reduces the weight of the structure.

Interior: Birch plywood triangular panels are attached to the frame with thin nails. Plywood surface - natural untreated wood. If you want to improve the interior, you can paint or varnish the plywood after installation.

Door, window, chimney: Door frame construction, door h2050x890mm, handle, lock, keys.

Panoramic window with transparent PVC cover.

A place for a fireplace. Fireproof stainless steel parts for the interior and exterior of the chimney. Fireplace and chimney not included.

Resistance: Dome constructions are calculated to withstand snow load up to 1.6 kN, and lawn load up to 34 m/s. If you need a higher load resistance, ask for advice.

Insulated Geodesic Dome Installation

We provide instructions and consultation for the installation process. You will need 2-6 installers to install one dome. Simple cordless carpentry tools and scaffold tower. 6 persons experienced installers install the dome in 5-6 working days. PVC cover is best installed when the temperature is positive. The warmer it is, the easier it is to install PVC. Installation of PVC cover is not recommended at temperatures of -5C and below

Workflow:

- Frame installation.

- OSB triangular panels are installed outside

- Diffuse film is installed over OSB

- Airflow spacers are installed above the diffusion films

- Entrance box and door

- PVC cover

- Insulation layers from the inside

- Interior plywood triangles

Maintenance: No special maintenance is required in warm weather. If you want to wash off dirt, use normal detergents and water. In winter, when there is a lot of snow, snow must be removed from the walls of the dome. Snow can damage the clear PVC cover panoramic window.

Important. This version of the dome is very airtight. A powerful adjustable ventilation system is required to control the humidity inside the dome.

Pictures of Insulated Geodesic Dome